Separator

High Efficiency Dynamic Separator:SEPCON Dynamic Separators improves the mill performance by avoiding over grinding of the material, and gives the required product fineness by efficiently separating the course particles from the fine particles. Our separators have achieved more than 80-90% efficiency in separation of fines

Advantages

Energy Saving: While the mill

is performing the grinding work, the Separator removes the finer

particles from the mill discharge and prevents them from being over

ground, thereby, saving energy.

Increasing Production: By extracting

part of the material from the grinding process, the separator creates

vacant space inside the mill allowing for more fresh material to

enter the mill, and thus increases the production ratio.

Flexibility Of Product Quality :

Flexibility to produce products of different qualities. This is

achieved by variation in rotor speed and air flow

Enhancement In Quality: Enhancement in product quality. We can get the finess in the range of 3000-6000cm2/gm by variation in rotor speed and air flow

|

|

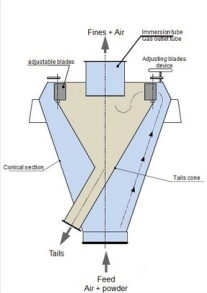

Grit / Static Air Separator:Grit Separator or Static Separator have no rotary parts to do the separation. The separation is done with the help of air, which carries and introduces the material inside the Separator.

Grit /Static Separator separates the small particles but it does not pick them up.

|

|

Cyclone Separator:The Cyclone Separator is used for air-product separation when working with non-dusty material. In case of dusty materials, cyclone is used as a primary separator and further separation of fine material is done using a bag filter.

SEPCON Cyclone Separator consists of a cylindrical vessel with tangential air inlet, central beveled air outlet and dust collecting hopper with protecting cone. The standard manufacturing range is selected after careful study and covers a wide range of flow rates. Standard separator are manufactured from mild steel sheets but alternatively materials like stainless steel or aluminium can be used. Chemical/heat/abrasion resistant coating inside the cyclone can be provided for special applications. |

|

Advantages